The Customer Experience

Experience means many things. An experience is a direct observation of or participation in events as a basis of knowledge. In other words, the customer experiences something through observation or participation. Experience also relates to a customer as the fact or state of having been affected by or gained knowledge through direct observation or participation. In other words, the customer has experienced things with the company that they base opinion on. Also, experience is related to an individual based on their practical knowledge, skill, or practice derived from direct observation of or participation in events or in a particular activity. Customers all have different experiences that make up their background. Individual experience is often related in the terms of degrees, certifications, and/or years of involvement in a particular thing.

In a nutshell, customer experience (CX) is something personally encountered, undergone, or lived through by a customer with a certain company. It is the product of an interaction between a company and a customer over the duration of their relationship. This interaction includes their attraction, awareness, discovery, cultivation, advocacy, and purchase and use of a service.

CX is simply the result of everything that makes up the company’s product or service delivery, visible or not.

Problems with Customer Experience Today

Many companies today only focus on the ‘touchpoints’–the critical moments when customers interact with the company and its offerings to establish the customer experience. This is often depicted in marketing as an experience map. Often, this is a narrow focus on what is important to the customer’s satisfaction at specific moments and often creates a distorted picture of the overall experience. This can lead a company to believe customers are happier with the company’s products and services than they actually are. This approach also diverts attention from the bigger and more important picture–the customer’s end-to-end journey.[i]

An emphasis on Operational Excellence within an company as the driver of the CX is important to carefully consider.

Experience-based Operational Excellence

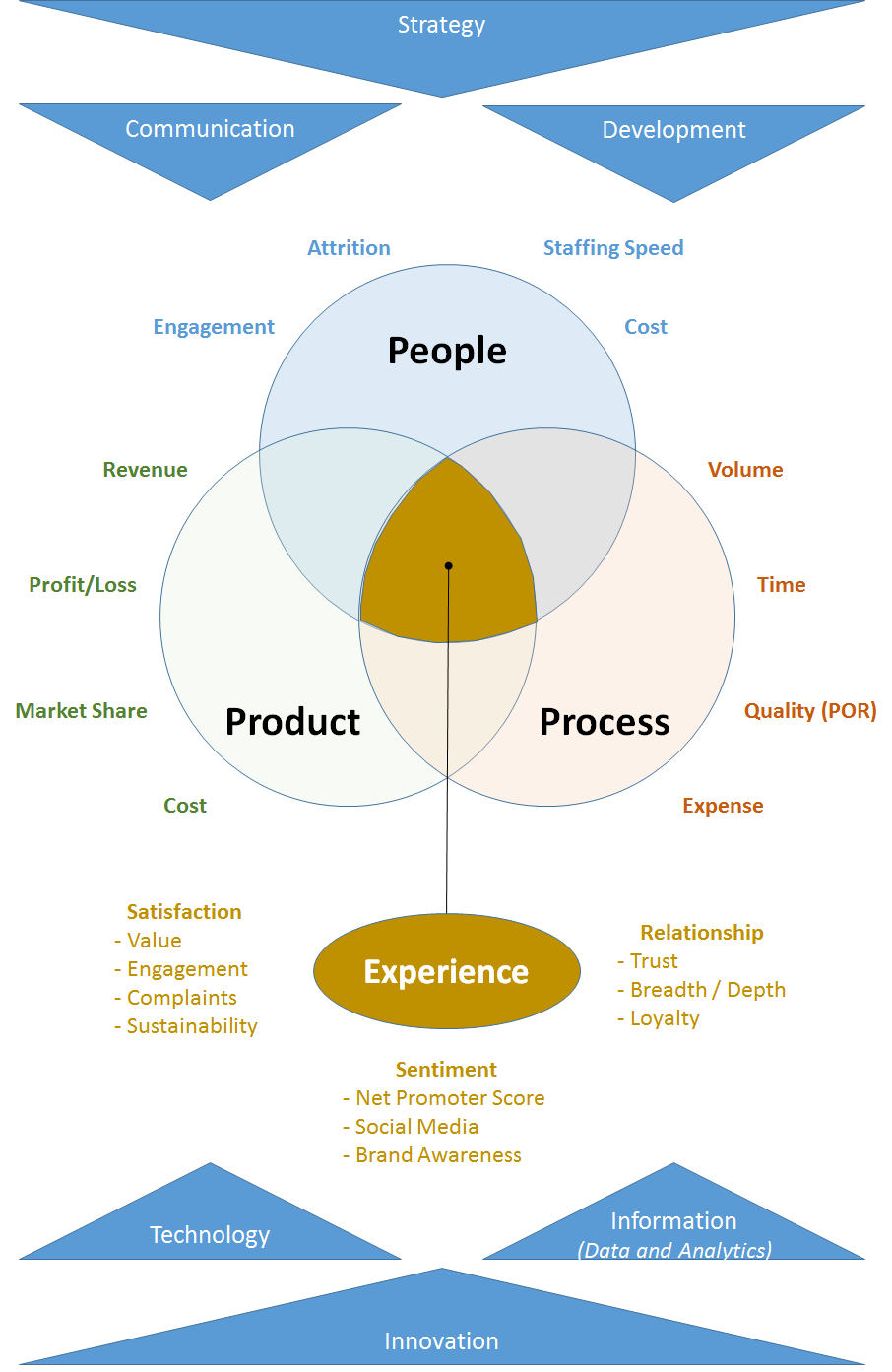

Operational Excellence (OpX), as an official business concept, has not been around very long and is often misconstrued. The best way to look at OpX is to think of it as an end-to-end enterprise-wide management practice that aligns everything in the organization toward driving excellence.[ii] From a perspective of the CX, OpX essentially represents an organization’s focus on all things that affect the customer’s experience (see Figure 1).

Figure 1: Experience-based Operational Excellence

Normally, companies view CX as a result of the product itself. Some broaden the view into the processes that impact the product delivery and many companies see OpX as nothing more than the application of process management and Lean Six Sigma improvement processes.[iii] In reality, true OpX represents the end-to-end enterprise-wise business management. The ‘experience’ is at the very center of where the product, process, and employee intersect–this is what the customer sees and feels. The entire experience is influenced by high-level company strategies, internal and external communication, and employee development. Everything within the company is supported by an innovative layer that includes technology and information.

Thus, everything in the organization is important in the CX equation and focusing simply on touchpoints will represent a lack of true focus on the CX. From a company’s perspective, there are several representative performance metrics that are important to the overall CX. A company cannot simply look at metrics like sales and net promoter score, but must consider all company performance as critical to the CX. There are many things that measure the experience, but can generally be referred to as satisfaction, sentiment, and relationship.

Summary

In summary, the traditional view of CX as a stand-alone activity represents a shortsighted view of what is important to the customer. Although much of what makes up OpX is out of the customer’s view, it all leads to the CX and must be considered and aligned.

[i] Rawson, A., Duncan, E., & Jones, C. (2013). The Truth About Customer Experience. Harvard Business Review.

[ii] Boothe, W., & Lindborg, S. (2014). Handbook to achieve operational excellence: A realistic guide including all tools needed. Ft Myers FL: Reliabilityweb.com.

[iii] Crabtree, R. (2010). Driving operational excellence: Successful lean six sigma secrets to improve the bottom line. Livonia MI: MetaOps Publishing.